Solar Inverter(String and Central)

Solar inverter is the key equipment for converting DC to AC in solar power generation system. Its structure mainly includes the following parts

1) Driver and power conversion unit:

This unit also includes the DC input part, which is mainly used to receive the DC power generated by the solar panel, including DC switch, input filter, input fuse, maximum power point tracker (MPPT) and other components.

It includes dc/dc converter, which is used to adjust voltage and current, convert DC energy into DC that meets the requirements of inverter input voltage, and is composed of output port, input port, conversion panel, control circuit, etc.

It also includes the inverter part, which is the core component of the whole system to convert DC power into AC power, including inverter chip, output filter, output fuse, etc.

2) Control unit: composed of microprocessor, control circuit, protection circuit, display screen, etc., it controls the output voltage and frequency of inverter and monitors the working condition of solar panel.

3) power management unit: the drive power of the whole system, the control unit power and the fan drive are powered by this unit.

The function of solar inverter is to convert the DC generated by solar panels into AC, which can be directly used for household and commercial purposes. The efficiency and reliability of the inverter are crucial to ensure the overall performance of the solar system. In addition, the inverter also has a variety of protection functions, such as overheating and overload protection, to ensure the safe operation of the system.

According to different power, solar inverters can be divided into centralized inverter, series inverter and other inverters (distributed inverter and micro inverter). The main difference between the three is that the single capacity of the inverter is different, and the application fields are different. Series inverter is mainly used in household distributed photovoltaic and small and medium-sized industrial and commercial roof photovoltaic.

Centralized photovoltaic inverter: it has the advantages of high output power, mature technology, high power quality and low cost, but its maximum power tracking voltage range is relatively narrow, the flexibility of component configuration is low, and the power generation time is short. It is mainly used in large-scale centralized photovoltaic power stations.

String type photovoltaic inverter: the inverter mode is to track the maximum power point of single string or several strings of photovoltaic modules separately, and then connect to the AC power grid after inversion. A string type inverter can have multiple maximum power peak tracking modules, and the unit capacity is generally below 200kW. The series PV inverter has wide maximum power tracking voltage range, flexible component configuration and long generation time. Moreover, with high power density and simple installation and maintenance, it can meet the requirements of indoor and outdoor applications, and is widely used in small-scale power stations, such as household distributed generation, small and medium-sized industrial and commercial rooftop power stations, etc.

Distributed inverter: it combines the advantages of centralized inverter of large-scale centralized PV inverter and decentralized MPPT tracking of series PV inverter to achieve low cost and high reliability of centralized inverter and high power generation of series inverter.

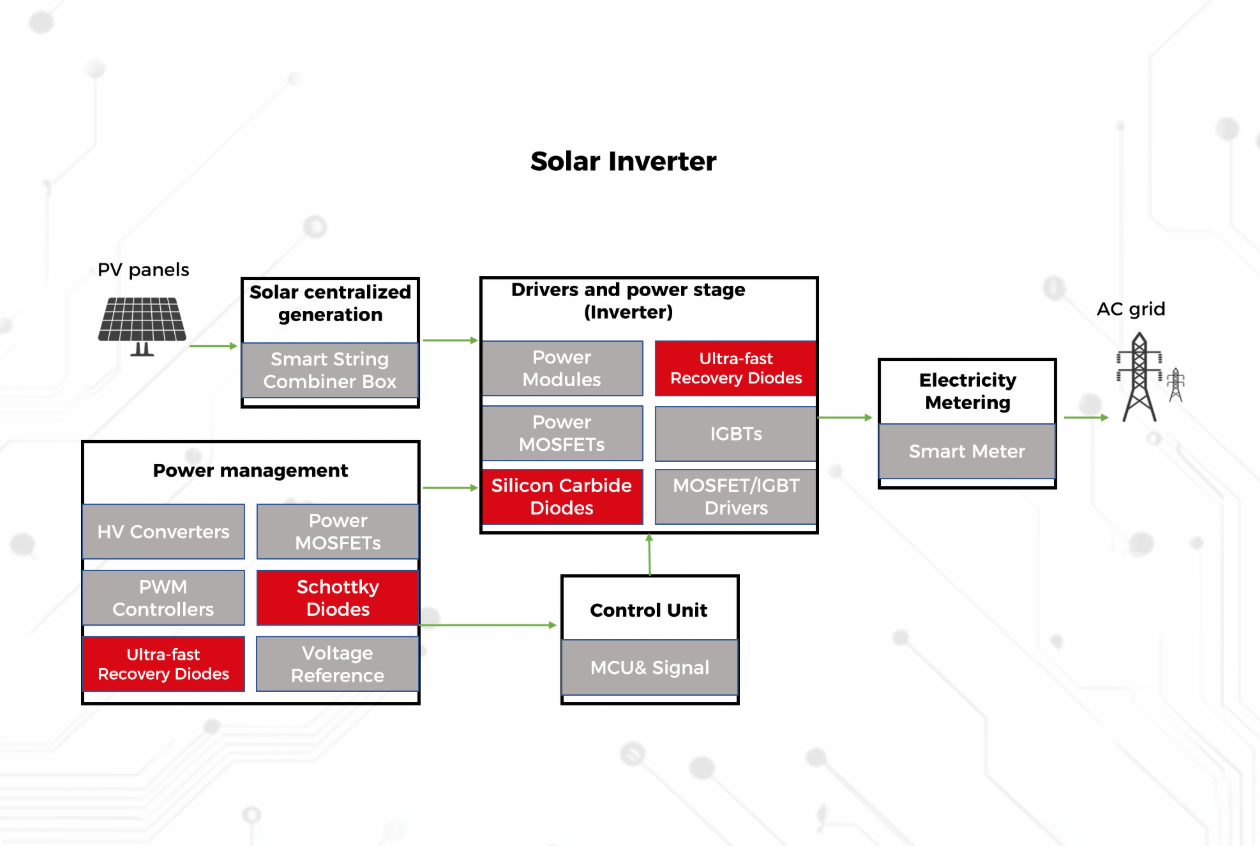

For the above solar inverters, please refer to the following block diagram.

Solar inverter mainly includes drivers and power stage, control unit and power management unit. The drivers and power stage also includes a DC-DC conversion stage to adapt to the voltage level and realize the maximum power point tracking (MPPT) function to maximize the transmission of energy from the panel, and a DC-AC conversion stage to correctly shape the current and voltage waveforms transmitted to the AC grid. The solar inverter has anti islanding function to ensure the safety of AC disconnection.

Since the power of solar series and multi series inverters ranges from several kilowatts to tens or hundreds of kilowatts of solar central inverter solutions, the trend is to use topologies with very high input voltages (up to 1700V).

For solar inverter, please refer to the following block diagram. In the orange box, SMC can provide the types of parts, including silicon carbide diodes, silicon-based Schottky diodes and ultrafast recovery diodes. There are corresponding material recommendations in the following list.

The ultra-fast recovery diode can be used in MPPT circuit of Drivers and power stage. The ultra-fast recovery diode of SMC has a lower forward conduction voltage drop VF, which can reduce the conduction loss; At the same time, it also has smaller reverse recovery time Trr and lower reverse recovery peak current Irrm, so it has smaller reverse recovery loss, so that the system can have higher system conversion efficiency; If the silicon carbide diode of SMC is used, the reverse recovery loss can be minimized, and the temperature of the switchers(IGBTs or MOSFETs) in the MPPT circuit can be significantly improved. Customers can choose the ultra-fast recovery diode or silicon carbide diode according to their actual needs. In power management unit, Schottky diode is the best choice for output rectifier diode. Schottky diode has the advantages of low forward conduction voltage drop VF and no reverse recovery loss. It is especially suitable for output rectifier of auxiliary power supply in power management unit. If the output voltage is below 200V, Schottky diode is particularly recommended; If higher output voltage is required, ultra-fast recovery diode is required.

For more material information, you can also click the orange box.

点击获赠免费样品!

点击获赠免费样品!