Smart Power Meter

Working Principle of Smart Meters

Energy Acquisition and Conversion

-

- The AC voltage and current in the power grid are proportionally converted into weak AC signals via a voltage divider (e.g., resistor network) and a current shunt (or current transformer).

- This process safely converts high voltage and high current to low voltage and low current for subsequent circuit processing.

Signal Conditioning and Digitization:

- The converted weak analog signals first undergo signal conditioning (including amplification, filtering, etc.) to make their amplitude and characteristics suitable for sampling by an Analog-to-Digital Converter (ADC).

- A high-precision, high-sampling-rate ADC inside the core metrology chip converts these continuous analog signals into discrete digital signals.

Calculation and Analysis:

- A dedicated microprocessor (or DSP core) inside the metrology chip performs real-time calculations using these digital samples and sophisticated algorithms (such as Fast Fourier Transform - FFT).

- Calculated parameters include not only basic ones like active power (P), reactive power (Q), apparent power (S), and energy (kWh, kVarh) but also voltage RMS, current RMS, power factor, frequency, etc.

- Advanced smart meters can also analyze harmonic content and monitor power quality events like voltage sags/swells.

Data Storage and Communication:

- The calculated data is stored in internal non-volatile memory (e.g., EEPROM or Ferroelectric RAM - FRAM) to prevent data loss after power failure.

- The main MCU (Microcontroller Unit) manages the entire system. Through a communication module (e.g., PLC, RF, 4G/5G), it uploads data to the utility's data center at preset intervals or in response to commands from the master station. It also receives commands from the data center, such as remote connect/disconnect, tariff switching, etc.

Display and Human-Machine Interaction (HMI):

- A local LCD display cycles through information like energy consumption, voltage, and current. Users can also press buttons to query more data.

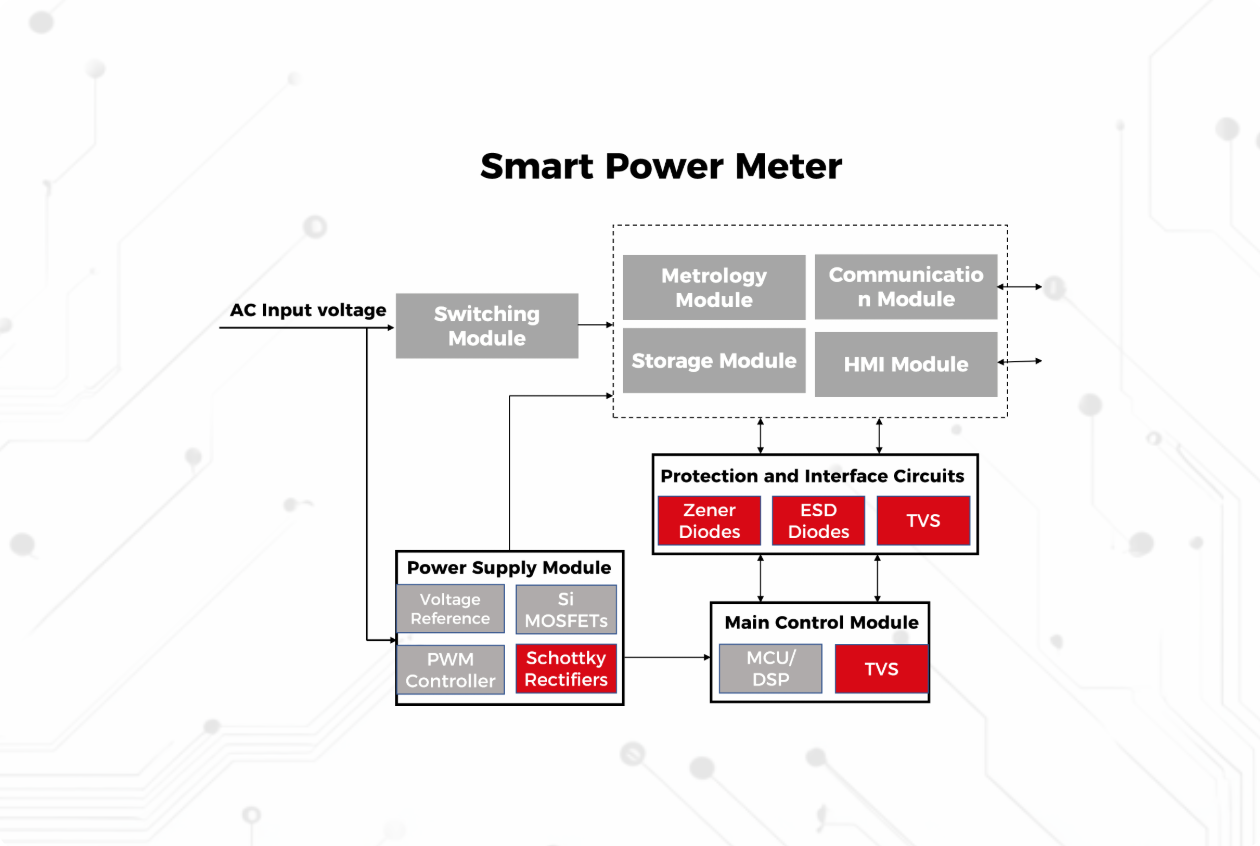

Components of a Smart Meter

Power Supply Module:

- Converts 220V/380V AC mains power to the low-voltage DC power (e.g., +5V, +3.3V, ±12V) required by internal chips (MCU, metrology chip, communication module). Switch-Mode Power Supply (SMPS) designs are typically used for high conversion efficiency.

Metrology Module:

- Core: Dedicated metrology chip (e.g., Analog Devices' ADE series, TI's MSP430+AFE, Maxim's MAXQ series).

- Input: Signals from the voltage sampling circuit and current sampling circuit.

- Function: High-precision measurement of all electrical parameters. It is the "brain" and "heart" of the meter.

Main Control Module:

- Core: Microcontroller (MCU), such as chips based on the ARM Cortex-M core.

- Function: Controls the metrology chip, reads/writes to memory, drives the LCD display, processes button interrupts, and manages the communication module. It is the "commander-in-chief" of the meter.

Communication Module:

- Local Communication: Responsible for communicating with the Home Area Network (HAN) or a data concentrator.

- Wired: Power Line Carrier (PLC)

- Wireless: RF (Micro-power wireless), Wi-SUN, LoRa, Zigbee, etc.

- Remote Communication: Direct communication with the utility's master station system (often used for industrial/commercial meters or scenarios without concentrators).

- Wireless: 4G (Cat.1)/5G, NB-IoT, etc.

Storage Module:

- Includes Flash memory for storing program code, and EEPROM or FRAM for storing frequently updated data (energy data, parameter settings, event records, etc.). FRAM, with advantages like fast read/write speed, low power consumption, and extremely long endurance, is gradually replacing EEPROM.

Human-Machine Interaction (HMI) Module:

- LCD Display: For displaying information.

- LED Indicators: e.g., pulse indicator, alarm indicator.

- Buttons: For local query and operation.

Switching Module:

- Built-in relay or solid-state relay for performing remote connect/disconnect operations.

Protection and Interface Circuits:

- This is the key area containing the core components mentioned in your query, protecting internal precision chips from external overvoltage, surges, Electrostatic Discharge (ESD), and other disturbances and damage.

Detailed Role of Core Protection Components

TVS Diode (Transient Voltage Suppression Diode)

- Working Principle: A clamping-type protection device. It has an extremely fast response time (up to picoseconds). When subjected to a instantaneous high-energy transient, the TVS diode rapidly changes its impedance from high to low, absorbing surge power up to several kilowatts, and clamps the voltage between its terminals to a predetermined value (Clamping Voltage, Vc), effectively protecting downstream precision components.

- Typical Applications in Meters:

AC Power Input Ports: Connected in parallel at the power input to absorb surge transients from the grid (e.g., induced lightning surges). High-power TVS tubes or dedicated surge protective devices (SPDs) are typically selected.

Communication Lines (e.g., RS-485, PLC port): Protect the communication chip's I/O ports from ESD and induced overvoltages. Low-capacitance TVS arrays are usually chosen to ensure signal integrity for high-speed communication.

ESD Protection: Low-power TVS diodes are placed on any ports that might contact humans (buttons, display interfaces, etc.) for ESD protection.

Zener Diode (Voltage Regulator Diode)

- Working Principle: Utilizes the reverse breakdown state of the PN junction, where the voltage across it remains essentially constant, enabling voltage regulation. Unlike the "transient" protection of TVS, Zener diodes focus more on continuous voltage clamping and regulation.

- Typical Applications in Meters:

Low-Power Regulation: Provides a simple, low-cost stable voltage for specific branches in non-isolated auxiliary power circuits.

Overvoltage Protection: Similar to TVS but mainly for longer-duration, lower-energy overvoltage events. Due to slower response time and lower power absorption, they are generally not used for high-energy surges.

Reference Voltage Source: Acts as a reference voltage source in simple analog circuits (high-precision metrology chips use more precise reference sources).

Schottky Diode

- Working Principle: Uses the rectifying effect of the potential barrier formed at a metal-semiconductor junction. Its key characteristics are low forward voltage drop (approx. 0.2-0.4V vs. 0.6-0.7V for standard silicon diodes) and very fast switching speed.

- Typical Applications in Meters:

Power Rectification: Used for high-frequency rectification on the secondary output side of Switch-Mode Power Supplies (SMPS). Their low forward voltage drop significantly reduces rectification losses, improves power conversion efficiency, and minimizes heat generation.

Reverse Polarity Protection: Connected in series within the power input path to prevent damage from reverse power connection.

Clamping and Freewheeling: Used as a freewheeling diode across inductive loads (relays, buzzers, etc.) to absorb the reverse induced electromotive force (back-EMF) generated when the coil is de-energized, protecting the driving transistor.

Summary of Differences:

- TVS: Addresses instantaneous, high-energy surges and pulses. Primary function: Protection.

- Zener Diode: Addresses sustained, low-energy over voltages. Primary function: Regulation.

- Schottky Diode: Leverages low loss and high speed. Primary function: Efficient rectification and freewheeling.

Market and Technology Development Trends

Market Trends:

- Global Adoption and Replacement Wave: Smart meters are replacing traditional electromechanical and electronic meters worldwide, especially in China, Europe, and North America. China has achieved near-full coverage in cities and is entering a new cycle of replacements.

- Policy Drivers: Government investments in smart grids, energy conservation & emission reduction policies, and carbon peak & carbon neutrality goals are key drivers for smart meter deployment.

- Growing Demand in Emerging Markets: Large-scale deployments are starting in Southeast Asia, Latin America, and Africa, representing new growth points.

- Value Extension: The market is shifting from pure hardware sales to integrated "Hardware + Software + Service" solutions, with increasing emphasis on data value.

Technology Trends:

- Higher Accuracy and Multi-Functionality: Evolving from simple metering to comprehensive measurement, supporting more precise harmonic analysis, power quality monitoring, load identification (Non-Intrusive Load Monitoring - NILM), etc.

- Dual-Mode / Multi-Mode Communication: To address communication blind spots and improve reliability, dual-mode communication (Power Line Carrier - PLC + Wireless - RF) is becoming mainstream. NB-IoT is seeing rapid growth in remote communication due to its wide coverage and low power consumption.

- Enhanced Security and Encryption: With increasing cybersecurity threats, new-generation smart meters incorporate advanced hardware security chips, supporting national cryptographic algorithms (e.g., SM series in China), secure boot, secure storage, and secure communication to safeguard data privacy and system security.

- Future-Oriented Design:

- Component Technology: Metrology chips are trending towards higher integration (SoC) and lower power consumption; wider adoption of new memory types like FRAM; performance (e.g., surge current capability, response speed) and integration (e.g., multi-channel TVS arrays) of protection components are also continuously improving.

Support for Distributed Energy Resources (DER): Adapting to the grid-connection metering and management of renewables like solar PV and energy storage.

Advanced Metering Infrastructure (AMI): Supporting flexible tariff strategies and demand response, acting as advanced sensors and nodes for the smart grid.

Software-Defined Meters: Enabling updates to meter functionality and algorithms via Firmware Over-The-Air (FOTA) updates, extending product lifecycle and reducing maintenance costs.

点击获赠免费样品!

点击获赠免费样品!