Industrial Air Conditioner Compressor Driver

Comprehensive Analysis of Industrial Air Conditioning Systems

Working Principle (Based on Vapor Compression Refrigeration Cycle)

-

- Compression: Low-temperature, low-pressure gaseous refrigerant is drawn into and compressed by the compressor, becoming a high-temperature, high-pressure gas. This process consumes electrical energy, which is converted into the internal energy of the refrigerant.

- Condensation: The high-temperature, high-pressure refrigerant gas enters the condenser, where it exchanges heat with outdoor air or cooling water, releases heat, and condenses into a medium-temperature, high-pressure liquid.

- Expansion: The medium-temperature, high-pressure liquid refrigerant passes through an expansion device (such as an expansion valve), where its pressure drops sharply, and its temperature decreases drastically, turning it into a low-temperature, low-pressure liquid-vapor mixture.

- Evaporation: The low-temperature, low-pressure refrigerant wet vapor enters the evaporator, absorbs heat from the chilled water (or air) flowing through the evaporator, and evaporates completely into a low-temperature, low-pressure gas. The cooled chilled water is then pumped to terminal units (such as fan coil units, air handling units) to provide cooling for the building.

Main Components

- Compressor: The "heart" of the system, it circulates the refrigerant and increases its pressure and temperature. Types commonly used in industry: Scroll, Screw, Centrifugal.

- Condenser: The "heat radiator" of the system, it releases the refrigerant's heat to the outside. Types: Air-cooled (cooled by fans blowing air) and Water-cooled (cooled by water circulated from a cooling tower).

- Expansion Device: The "throttling valve" of the system, it controls refrigerant flow and reduces its pressure. Common types: Thermostatic Expansion Valve (TXV), Electronic Expansion Valve (EEV), capillary tubes.

- Evaporator: The "heat absorber" of the system, where the refrigerant evaporates and absorbs heat from the secondary coolant (water or air).

- Refrigerant: The working fluid circulating in the system, e.g., R134a, R410A, R32, R1234ze.

- Control System: The "brain" of the unit, including PLCs, sensors, and Human-Machine Interfaces (HMI). It monitors operating parameters (pressure, temperature, current, etc.) and controls the coordinated operation of various components.

- Auxiliary Components: Receiver, oil separator, filter-drier, sight glass, etc.

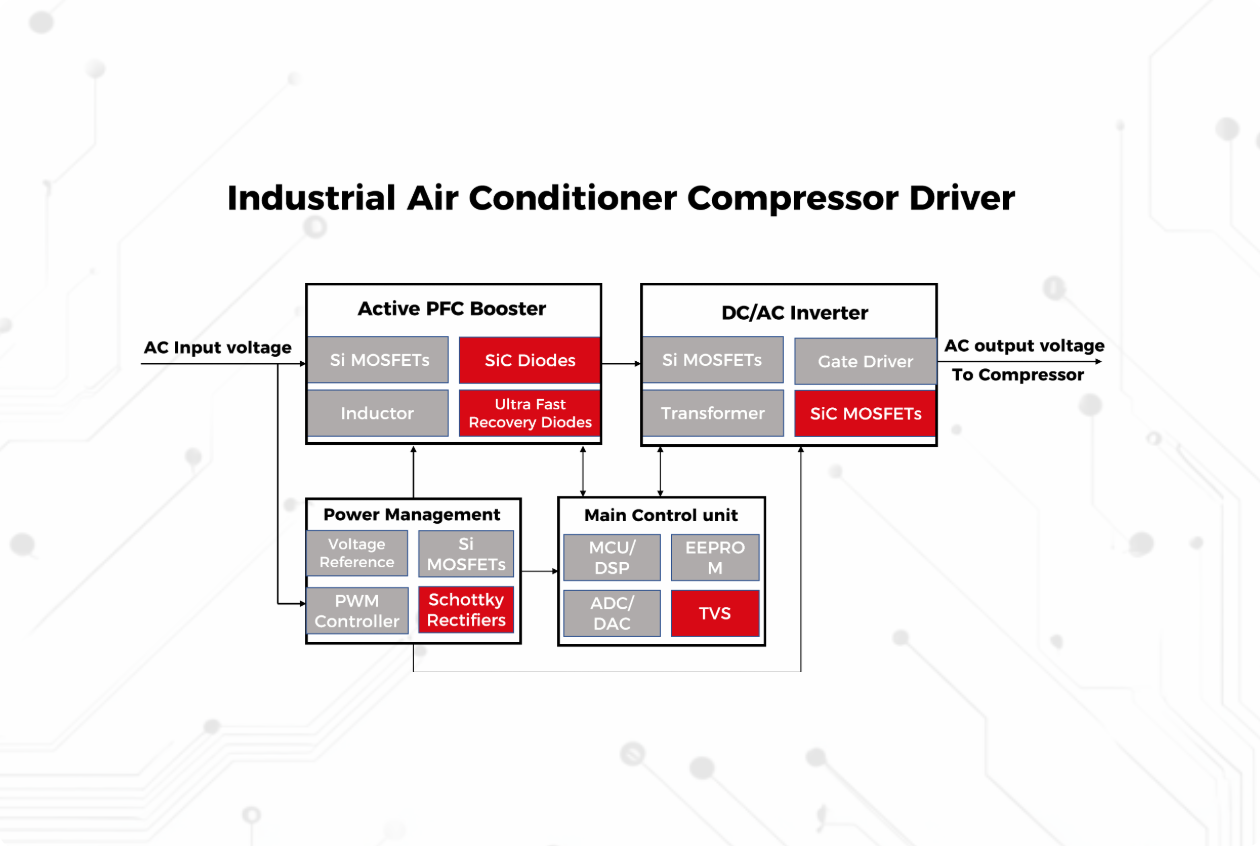

Core Focus - Detailed Explanation of Air Conditioning Compressor Drives

Working Principle of the Variable Frequency Drive (VFD)

- Rectification: First, the input AC power with fixed frequency (50/60Hz) and fixed voltage is converted into DC power by a rectifier bridge.

- Filtering: The rectified DC power contains ripple. It is filtered by the DC bus capacitors to obtain smooth DC power.

- Inversion: This is the core环节. Based on commands from the control system, the inverter bridge (composed of power switching devices like IGBTs or MOSFETs) switches on and off at extremely high frequencies, "chopping" the smooth DC power into three-phase AC power with adjustable frequency and voltage.

- Control Principles:

V/f Control: To maintain constant motor flux and avoid magnetic saturation, the voltage (V) applied to the motor must be changed proportionally when the frequency (f) is changed. This is the most basic control method.

Vector Control: A more advanced control method. Through complex mathematical transformations (Clark/Park transforms), the motor's current is decomposed into the magnetizing current (which generates the magnetic field) and the torque current (which generates torque), which are controlled precisely and independently. This enables fast, high dynamic response, controlling the AC motor like a DC motor, even providing high torque at low speeds.

Direct Torque Control (DTC): Another high-performance control method that directly controls the motor's magnetic flux and torque, offering even faster dynamic response.

Core Components of Compressor Drives

- Rectifier Unit:

- DC Bus:

- Inverter Unit:

- Controller:

- Current/Voltage Sensors:

- Gate Drive Circuit:

- Cooling System:

Diode Rectifier Bridge: The simplest and most economical solution, but energy can only flow unidirectionally from the grid to the DC bus.

IGBT Rectifier / PWM Rectifier Bridge: Uses controllable IGBTs instead of diodes, enabling bidirectional power flow, sinusoidal grid current, improved power factor (PF), and elimination of harmonic pollution. This is standard in high-end drives.

Electrolytic Capacitors: Their function is energy storage and filtering. Their capacity, voltage rating, and lifespan (usually rated in hours) are key factors determining drive reliability. High temperature is their main enemy.

IGBT (Insulated Gate Bipolar Transistor): It is the core switching device of the inverter bridge, handling high voltage and high current switching tasks. Its switching speed, conduction losses, and voltage rating directly determine the drive's efficiency and performance. Modern IGBT modules often integrate multiple chips and include drive and protection circuits.

SiC MOSFET (Silicon Carbide Metal-Oxide-Semiconductor Field-Effect Transistor): This is a new generation of semiconductor technology. Compared to traditional silicon-based IGBTs, SiC devices offer advantages such as extremely fast switching speeds, very low switching losses, high-temperature tolerance, and low on-resistance. Drives using SiC devices can achieve higher switching frequencies, reducing the size of peripheral passive components (inductors and capacitors) and increasing system efficiency and power density.

DSP (Digital Signal Processor): It is the "brain" of the drive, responsible for executing all complex control algorithms (e.g., V/f, Vector Control), acquiring current and voltage signals in real-time, generating PWM waveforms to control IGBT switching, and handling communication and protection logic. Its processing speed and capability are crucial.

Used to detect key parameters like DC bus voltage and output current in real-time and provide feedback to the DSP for closed-loop control. Common solutions include Hall effect current sensors, shunt resistors with isolated amplifiers.

Located between the DSP and the IGBTs, its function is to amplify and isolate the low-voltage PWM control signals from the DSP, converting them into high-power signals capable of directly driving the IGBT gates.

Heat sinks and cooling fans. IGBTs and the rectifier bridge generate significant heat during operation. An efficient cooling system is essential to dissipate this heat into the environment; otherwise, the components will overheat and fail.

Market and Technology Development Trends

Market Trends

- High Efficiency, Energy Saving, and Environmental Protection: Against the backdrop of high global energy prices and "Dual Carbon" goals (Carbon Peak and Carbon Neutrality), demand for high-efficiency units continues to grow. Energy efficiency standards (e.g., China's GB19577, ASHRAE 90.1 in the US) are becoming increasingly stringent.

- Increased Penetration of Inverter Technology and Intelligence: Inverter technology is becoming ubiquitous, moving from high-end applications to mid- and low-end markets. Intelligent control, remote monitoring, and predictive maintenance are becoming standard features, helping users reduce operating costs.

- Low-GWP Refrigerant Transition: With the implementation of the Kigali Amendment, the phase-out of traditional refrigerants with high Global Warming Potential (GWP) (e.g., R410A) is accelerating. Demand is rapidly growing for environmentally friendly alternatives such as R32, R1234ze, R1233zd, R513A, CO₂ (R744), Ammonia (R717), and Propane (R290).

- Growth in Niche Markets: Precision air conditioning demands in specific sectors such as data centers, new energy (e.g., lithium battery production facilities), medical pharmaceuticals, and rail transportation are creating new growth opportunities.

- Integrated Solution Providers: Customers are no longer satisfied with purchasing single products but prefer procuring integrated solutions and services encompassing design, installation, operation, maintenance, and energy-saving retrofits.

Technology Development Trends

- Compressor and Drive Technology:

- System Design and Optimization:

- Intelligence and Digitization:

- New Refrigerant Application and System Adaptation: Development of dedicated compressors, heat exchangers, and safety control systems for new environmentally friendly refrigerants that may be flammable/explosive (A2L, A3) or operate at high pressures (CO₂).

Magnetic Bearing Centrifugal Compressors: Utilize magnetic bearing technology, are oil-free, completely eliminate mechanical friction, are highly efficient, and excel particularly at part-load performance. They are a key future direction for large chillers.

Widespread Application of SiC/GaN Power Devices: The use of SiC MOSFETs in compressor drives will move from experimentation to mass production, significantly improving system efficiency (especially at part load), power density, and reliability.

High-Speed Permanent Magnet Synchronous Motors: Perfectly matched with VFDs, their efficiency far exceeds that of traditional induction motors. They are the mainstream configuration for centrifugal and screw compressors.

Full Variable Frequency Design: Not only the compressor but all moving components like fans and pumps use variable frequency drives, achieving optimal energy efficiency matching for the entire system.

Free Cooling: Utilizes low outdoor air temperatures during transitional seasons and winter to provide cooling directly, bypassing the compressor, which can significantly reduce energy consumption.

Heat Recovery Technology: Recovers condensation heat for use in domestic hot water or process heating, enabling cascaded use of energy.

AI and Big Data: Based on operational data, AI algorithms are used for load forecasting, optimal start-stop, fault diagnosis, and energy efficiency optimization.

Digital Twins: A complete virtual model of the physical unit is built in a virtual space for design verification, performance prediction, and remote maintenance guidance.

IoT and Cloud Platforms: Units seamlessly connect to IoT cloud platforms, enabling centralized monitoring of vast numbers of devices, energy management, and cross-regional collaborative optimization.

点击获赠免费样品!

点击获赠免费样品!