Washing Machine Motor Driver

Working Principle

The core function of a washing machine motor drive power supply is to convert utility AC power into the electrical energy required by the motor through power electronics technology. The typical workflow is:

1. Rectification & Filtering: 220V/50Hz AC input is converted to 310V DC via a bridge rectifier and capacitive filtering.

2. Inverter Control: An H-bridge inverter circuit composed of IGBTs or MOSFETs generates variable-frequency three-phase AC output using PWM modulation techniques.

3. Drive Protection: Integrated protection circuits (overcurrent, overvoltage, overtemperature) provide real-time monitoring of motor speed and torque.

System Architecture

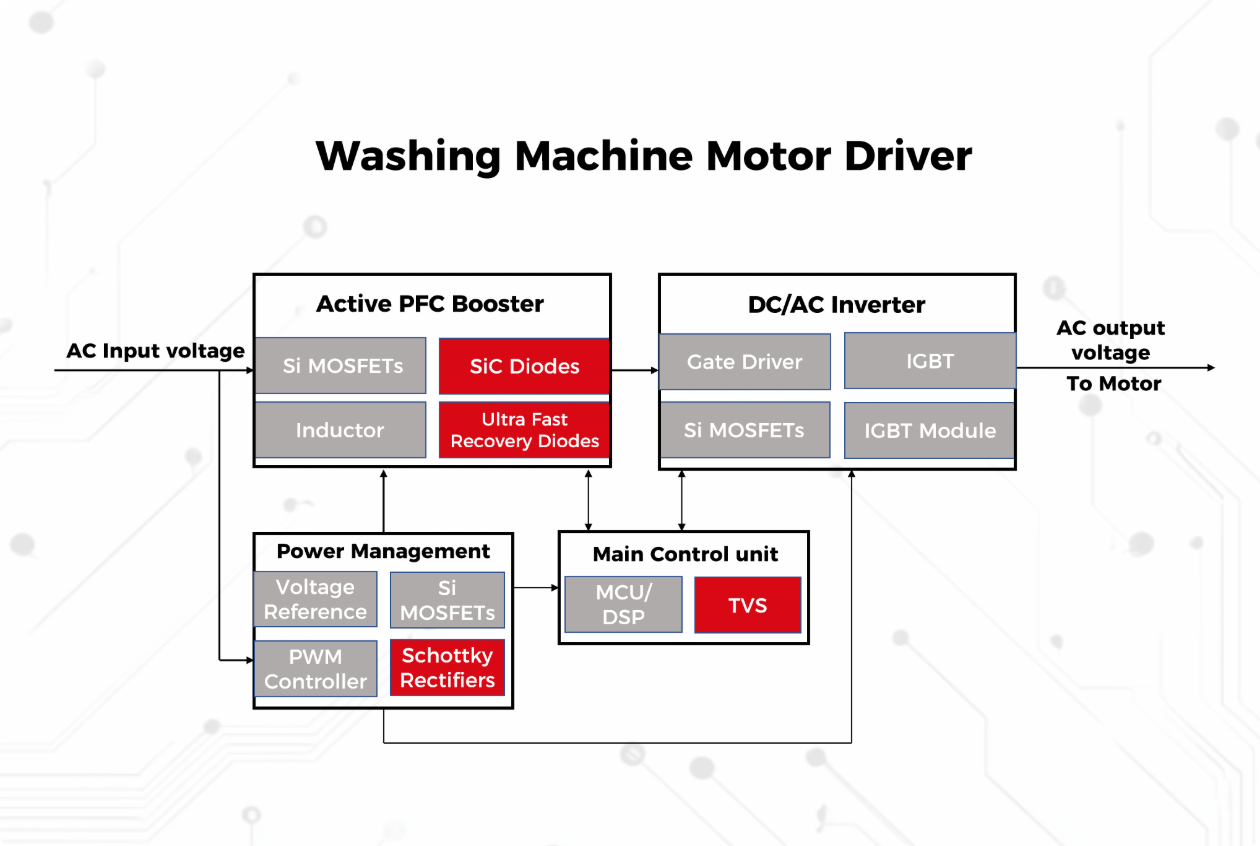

Modern solutions predominantly employ a three-tier architecture:

1. Power Module: Contains the rectifier unit and Intelligent Power Module (IPM).

2. Control Unit: Features a digital controller based on an MCU (e.g., ARM Cortex-M) or DSP.

3. Sensor Feedback: Employs Hall sensors and encoders to form a closed-loop control system.

Advanced models increasingly utilize BLDC (Brushless DC) motor drive solutions, achieving efficiencies exceeding 90%.

Market Development Trends

Technical Directions:

- Adoption of Wide-Bandgap Semiconductor (WBG) devices (SiC/GaN).

- Optimization of adaptive variable-frequency control algorithms.

- Pre-research on wireless power transfer technologies.

Product Forms:

- Modular designs (decoupling drive power supply from main control board).

- Compliance with IEC 60730 safety standards.

Market Landscape:

- Global market size projected to reach $4.2 billion by 2025.

- Chinese manufacturers hold ~60% share in mid-to-low-end market segments.

- High-end segments remain dominated by Japanese (Toshiba, Panasonic) and European (Siemens, Electrolux) manufacturers.

The advantages of SMC

SMC, as a globally leading power semiconductor device manufacturer with nearly 30 years of history, can provide customers with the most advanced, efficient, and cost-effective third-generation silicon carbide MOSFETs and silicon carbide JBS diodes. In addition, SMC has unique experience in silicon-based power diode devices, and its best-selling high-power ultra-fast recovery diodes, high current Schottky diodes, and other products are highly praised by customers worldwide. SMC's power semiconductor devices can provide higher efficiency, better reliability, good delivery time, and competitive prices for your products. SMC's professional service team around the world allows you to experience the ultimate customer service experience and safeguard your product design.

点击获赠免费样品!

点击获赠免费样品!